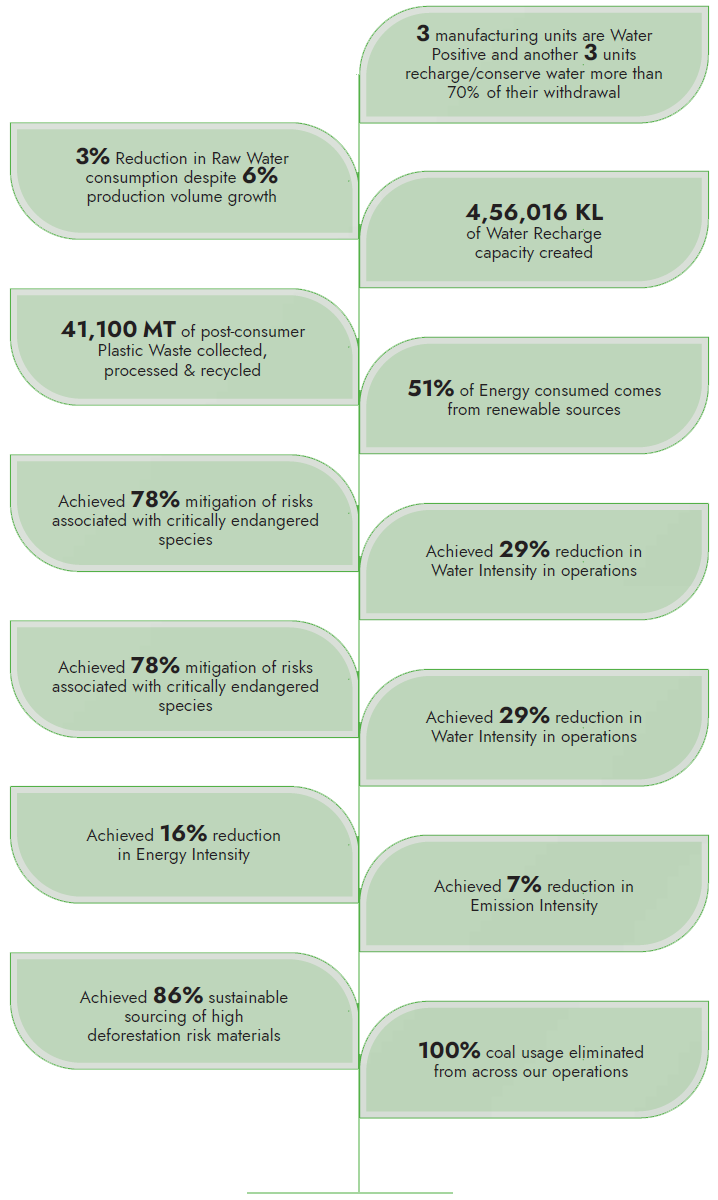

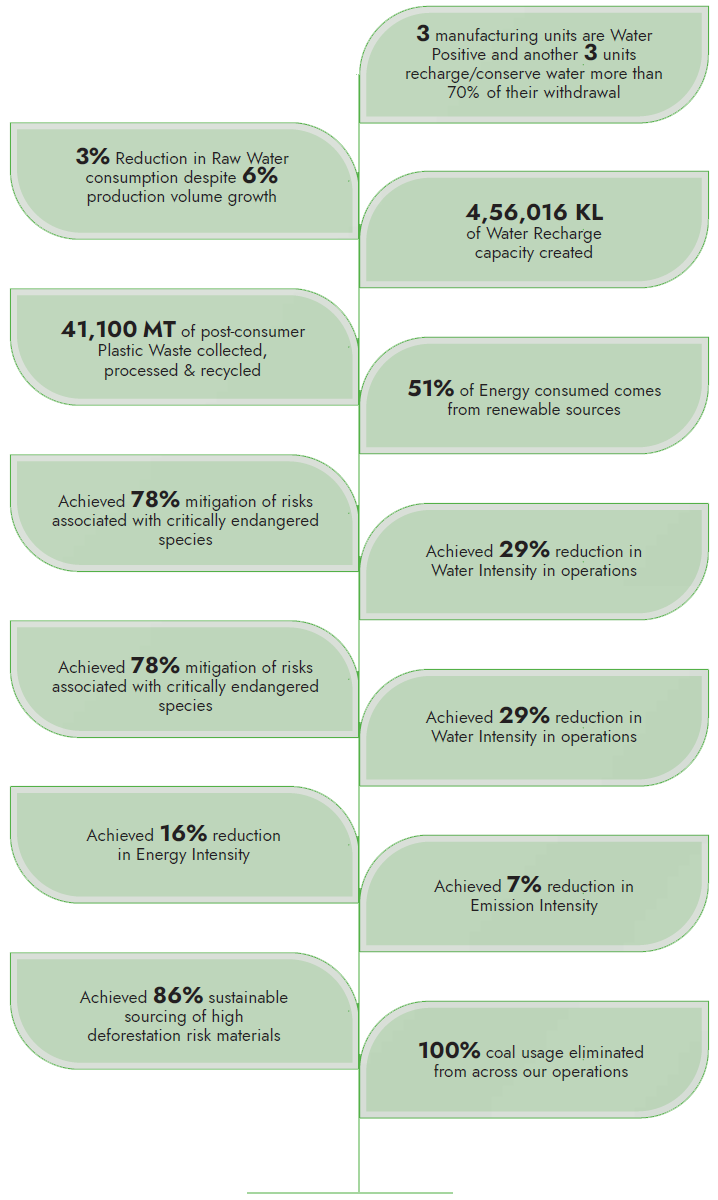

Key Highlights of FY 2023-24

Our Natural Capital reflects our commitment to become Net Zero Emissions by 2045. Across our manufacturing locations and offices, we have been combining energy conservation practices with a shift towards renewable energy sources to build a more sustainable and resilient energy system that benefits both present and future generations. With these efforts, we are moving towards creating a cleaner, greener future for our planet.

At Dabur, we understand that energy conservation and transitioning to renewable energy sources are pivotal steps towards achieving sustainability and combating climate change. This not only helps mitigate environmental impacts but also contributes to cost savings and energy security. Dabur does not have any operations/offices in and around ecologically sensitive areas (such as national parks, wildlife sanctuaries, biosphere reserves, wetlands, biodiversity hotspots, forests, coastal regulation zones etc.).

Dabur has consistently led the way in energy conservation across our operations, aiming to decrease reliance on non-renewable fossil fuels, enhance energy productivity, and lower operational expenses to combat the effects of Climate Change. Effective energy management and conservation serve as the cornerstone of our environmental sustainability strategy.

We have been implementing energy-saving initiatives to bolster our energy efficiency. Over recent years, significant investments have been made in expanding our Juices portfolio, aligning with our growing focus on Foods & Beverages. Despite beverage manufacturing demanding substantial energy and water resources, we have successfully reduced our energy intensity (GJ/MT) by 16% from the base year.

Some of the key initiatives taken this year are:

| Steps taken on Energy Efficiency | Capital Investment (in Lakhs) |

|---|---|

| Use of energy-efficient motors & devices | 585 |

| Efficiency Improvement on high energy equipment, Variable Frequency Drives (VFDs), etc. | 300 |

| Energy conservation towards reduced Compressed air consumption & energy efficient air compressors | 169 |

| Lighting Load Optimization using LEDs, Heat recovery systems, Process improvement, Line integration, IoT and interlocking of equipment | 72 |

| Total Investment | 1,126 |

This year, Dabur continued its holistic approach by focusing on Scope 1 (i.e. emissions from sources directly owned or controlled by the company) and Scope 2 (i.e. emissions from the use of energy indirectly purchased and used by the company) emissions and therefore began monitoring its electricity and fuel data from production facilities, including offices, warehouses, daycare centers and employee dormitories. This approach helped identify key opportunities across the value chain and improve sustainability.

For the past several years, we have been working towards enhancing both “Energy Efficiency” and the use of “Green Energy” within our operations. This is reflected in the three new biomass boilers that were commissioned at our manufacturing units in FY 2023-24.

In FY 2023-24, 51% of Dabur's total energy consumption (scope 1 & 2) came from renewable sources. With the initiatives executed during the year, usage of renewable energy is expected to increase to 55% by 2024-25.

We have also been promoting Solar Energy within the community. Details of this intervention have been provided in the Social & Relationship Capital section of this report.

In FY 2023-24, we continued to build on our emission reduction program under Project Prakriti and have now started baselining our Scope-3 emissions for all the material categories. Scope 3 encompasses indirect GHG emissions across our entire value chain, with a focus on upstream categories such as upstream transportation and the raw material footprint (Scope-3 emissions from purchased goods), which include emissions from our suppliers and their corresponding feedstocks, as well as downstream categories like downstream transportation and product use and disposal. This comprehensive approach will help us craft an emissions reduction roadmap across the value chain. Collaboration with key suppliers and service providers continues and reduction action plans are being further developed.

| Parameter | Unit | FY 2023-24 |

|---|---|---|

| Total Scope 3 emissions (Break-up of the GHG into CO2, CH4, N2O, HFCs, PFCs, SF6, NF3, if available) | tCO2e | 5,22,766 |

| Total Scope 3 emissions per rupee of turnover | tCO2e/lakh rupees | 0.57 |

| Total Scope 3 emission intensity (optional) – the relevant metric may be selected by the entity | -- | -- |

We have baselined our Scope 3 emissions for material categories in the reporting financial year. Above scope 3 emissions are calculated and extrapolated based on the results of the LCA study done for products contributing to 50% of revenue and 58% of the production volume. For Capital Goods, Employee Commute and Business Travel Scope 3 categories, the emissions have been calculated using spend-based and distance-based methods, respectively. We intend to gradually transition to calculating emissions using the most accurate methods, viz. actual supplier-specific data for Capital Goods and fuel-based emission calculations for Employee Commute and Business Travel and will update the emissions accordingly.

We are committed to continuously improving the accuracy and completeness of our scope 3 emissions reporting. As we enhance our data collection processes and engage further with our value chain partners, we will adopt more precise calculation methodologies to strengthen the disclosures.

Water consumption and conservation in industries play a crucial role in reducing environmental impact and leaving a cleaner footprint. Water is used within our manufacturing plants and offices for various purposes, such as manufacturing processes, cooling, cleaning, and sanitation. At Dabur, we have been continuously working on optimising water use, reducing waste, and implementing water-efficient technologies to minimize our water footprint while maintaining operational efficiency. This not only helps conserve precious freshwater resources but also reduces energy consumption associated with water pumping, treatment, and heating.

In line with its ESG commitment, we are today monitoring water withdrawal and usage data not only within our manufacturing sites, but also at non-production sites like Offices, Warehouses, and Nurseries. This approach has helped identify opportunities across the value chain and improve sustainability.

We have put in place programs to better understand the patterns and impacts of our water withdrawal, use and discharge. These include the construction of rainwater harvesting systems within our manufacturing facilities and creation and rejuvenation of ponds within the communities to catch rainwater.

At all of Dabur's operations, there is a strong focus on reducing water intake by utilising treated wastewater within the process. Dabur units operate in line with the Consent to Operate (CTO) conditions & Pollution Control Board (PCB) norms. Based on our internal assessment, three of our manufacturing units are today Water Positive and another 3 units recharge/conserve water more than 70% of their withdrawal. We have enhanced our Water conservation capacity within our factories to 2,47,589 KL.

In addition, various community water conservation programs and Rainwater harvesting programs are in place, thereby contributing to water accrual. Our efforts have also helped enhance the water conservation capacity within the community to 2,08,427 KL, marking a 355% jump over the previous year. Details of these interventions have been presented in the Social & Relationship Capital section of this report.

Our initiatives have helped reduce our water intensity (KL/MT) by 29% across India from the base year, despite our growing focus on the beverage portfolio. In FY 2023-24 alone, our interventions have helped reduce water intensity by ~9%.

Dabur is also committed to implementing the 3 Rs (Reduce, Reuse and Recycle) principle for conservation of water. Our manufacturing units are continuously putting efforts to reduce the raw water extraction and to increase the utilization of recycled water into processes. At all manufacturing locations, suitable and efficient wastewater treatment systems like sewage treatment plants (STP) and effluent treatment plants (ETP) are installed, and treated wastewater is used for various purposes.

Some of the key initiatives which were taken in the areas of water conservation and management in FY 2023-24 include:

The year 2023-24 saw Dabur undertake a detailed Water Risk Assessment, covering 100% of our manufacturing operations. Utilising the WRI Aqueduct tool and Central Ground Water Board’s (India) parameters, the physical water risk assessment encompassed a wide range of parameters, including water stress, water depletion, interannual variability, seasonal variability, drought, and flood risk.

In addition to establishing a baseline for water risk, we also conducted scenario analyses for the time horizon 2030 and 2050, under three different scenarios:

These scenarios provided insights into potential future water-related risks, allowing us to formulate robust strategies for mitigating them.

We are committed to forming a fair, sustainable, and ethical relationship with our suppliers. At Dabur, responsible sourcing practices is an integral part of our business strategy with the ultimate goal of ensuring decent working conditions, environmentally responsible practices, and ethical behaviour across our value chain. This is also reflected in our Supplier Code of Conduct (SCOC).

Today, we source a wide range of raw and packaging materials, like Honey, Amla, Sugar-Jaggery, Vegetable Oils, Fruit Pulps & Concentrates, Maize Derivatives like Sorbitol, Dextrose Monohydrate, Aromatic Essential Oils, Psyllium Husk, Spices, Medicinal Herbs, Gold & Silver, Paper-based Packaging Materials like mono-cartons, corrugated boxes, polymer-based Packaging Materials like PET, HDPE, PP etc, flexible packaging like laminates, labels, sleeves, Glass bottles and metal caps. Our sourcing function focuses on 3 major result areas: (1) Cost Saving; (2) Material Availability; (3) Sustainability in Sourcing.

FY 2023-24 has broadly witnessed a deflationary environment in material cost. While several key raw materials like Vegetable Oils, Honey, and Polymer & Paper based Packaging Materials, Medicinal Herbs saw inflationary pressures softening, and some categories like Spices, Psyllium Husk and Orange Concentrates witnessed high inflationary pressures. Dabur has managed its sourcing well and delivered an overall deflation of 2.25% (against WPI deflation of 0.70%) in material cost.

The year saw Dabur progressing well on the sustainability front in sourcing. As stated in Dabur’s responsible sourcing policy, we are guided by the four foundation pillars of ESG: Good For society, Good for Environment, Good for Consumers and Good to Abide by The Law.

Through regular risk assessments of our raw material sources, we ensure that our sourcing practices also prioritise sustainability. We have set ourselves the target of 100% sustainable sourcing of high deforestation risk materials like beverage cartons, paper, Palm Oil, etc. by FY 2025-26. In 2023-24 financial year, we have ensured that 86% of the high deforestation risk materials are sustainably sourced.

We are also actively addressing risks associated with the procurement of critically endangered herbs by investing in cultivation and sustainable management initiatives. By FY 2025-26, our aim is to source 100% of these herbs through sustainable contract farming or similar practices, with a further commitment to achieving no net loss by 2050. In the year 2023-24, we have achieved 78% sustainable sourcing level for the critically endangered herbs.

Major progress made on these fronts during the year are:

Recognizing the enduring importance of biodiversity conservation for both our business and for society, Dabur has developed a robust Biodiversity Policy aligned with the major goals of the Convention on Biological Diversity (CBD 1992). Our efforts to enhance biodiversity are integrated in our Net Zero Emissions Roadmap.

Our commitment extends to refraining from any business activity that could irreversibly harm biodiversity. We also do not have any operational sites or manufacturing locations in close proximity to nationally significant or ecologically sensitive, high biodiversity value and protected areas.

As part of our mission to preserve ecosystems and support conservation of rare and endangered species through our Biodiversity Management Plans, Dabur has joined hands with relevant stakeholders and local communities to bolster the population of these species in their natural habitats. Our efforts include the establishment of state-of-the-art greenhouses in Pantnagar (Uttarakhand) and Banepa (Nepal), along with satellite nurseries and demo cultivation sites nationwide. These mother greenhouses are completely run by women, giving an added push to our diversity agenda.

These greenhouses focus exclusively on cultivating medicinal plant saplings, which are distributed to local farmers free of charge. In 2023-24 alone, we distributed 46,22,484 plant saplings. Not only does this initiative promote large-scale cultivation of standardised medicinal plants, but it also safeguards rare and endangered species from extinction. For the past over a decade, Dabur has beat the odds to do critical conservation by working together with farmers, tribals and forest-based communities. Together, we promote sustainable cultivation practices and ensure socio-economic development. Our interventions have helped enhance the income of these communities by up to 50%.

In 2023-24, we engaged with 15 NGOs across the country. Together, we train the farmers and forest-dependent communities on the sustainable cultivation of these herbs. These partner NGOs are:

| Partner NGO | State |

|---|---|

| Human India | Uttarakhand |

| Alaknanda Ghati Shilpi (AAGAAS) Federation | Uttarakhand |

| Baitarni Initiative | Odisha |

| The Covenant Centre For Development (CCD) | Chhattisgarh & Tamil Nadu |

| High Altitude Plant Physiology Research Centre (HAPPRC, HNB Garhwal University) | Uttarakhand |

| Janakalyan Welfare Society (JKWS) | Andhra Pradesh |

| Dr. Balasaheb Sawant Konkan Krishi Vidyapeeth (KKV) | Maharashtra |

| The Energy and Resources Institute (TERI) & Van Panchayat Pichal Tanda (VPPT) | Uttarakhand |

| Shri Umiya Majoor Kamdar Sah. Mandli Ltd, Vandhay (SUMS- Bhuj) | Gujarat |

| Sujagrati Samaj Sevi Sanstha | Madhya Pradesh |

| Biodiversity Tourism & Community Advancement (BTCA) | Himachal Pradesh |

| TRAAHI | Assam |

| Jan Kalyan Sewa Sansthan (JKSS) | Uttar Pradesh |

| Jagran Jan Vikas Samiti (JJVS) | Rajasthan |

| Sanjeevani | Uttar Pradesh |

In addition, Dabur is also working with the Center for International Forestry Research (CIFOR) and World Agroforestry (ICRAF) on a mega initiative aimed at improving trees, fruits, medicinal and aromatic plantation practices on farms and outside forests areas, using agroforestry across Uttar Pradesh, Haryana, Rajasthan, Odisha, Andhra Pradesh, Assam and Tamil Nadu. This initiative, which is working towards increasing the tree cover outside demarcated forest areas and on farmlands, will go a long way towards helping India achieve climate mitigation targets in the forestry sector, while also supporting sustainable livelihoods for communities. Under this project, we are focusing on the domestication of selected medicinal tree species and medicinal plants, besides establishing satellite nurseries in states to ensure the availability of quality planting material for the selected plant species.

Our ambitions are huge, but, with the right strategies and enough resources, they are achievable. In the year 2023-24, Dabur engaged 10,877 farmers in the cultivation and collection of medicinal plants and herbs. Our target is to sustainably cultivate medicinal and aromatic plants across 15,000 acres of land by FY 2029-30. In FY 2023-24, our efforts have helped us bring 10,145 acres of land under cultivation of medicinal plants, a 31% jump over 2022-23.

At Dabur, we have been consciously working towards substituting materials from finite, fossil-based sources with solutions that are renewable, recyclable and store carbon. As part of this mission, we reuse resources and materials as well as minimise waste as we work towards promoting a circular economy.

We have been working continually to use less paper, which in turn leads to saving the trees from being cut down, by adopting technology. We have been promoting paperless meetings, digitizing the way we operate daily to reduce paper consumption, and using QR codes for goods invoices. We have also undertaken training and awareness programs to minimize the use of printing paper and to use both sides of the paper to print, if the need arises.

In terms of packaging, we have executed projects across all verticals during the year with respect to product packaging design changes, weight reduction and transition to sustainable packaging materials. Along with paper, we also track the consumption of Plastics (Rigid), Laminates and Glass used for packaging purposes. Due to these innovative projects, the cumulative potential reduction in the consumption of the mentioned packaging materials has been 539.96 tonnes. We also reused approximately 400 MT of discontinued packaging material paper and 60 MT of plastic for in-house activities, thus avoiding equivalent scarp generation and procurement of new material.

At Dabur, we understand that waste-reducing, reusing, recycling, management, and the promotion of a circular economy are integral components of sustainable development and environmental stewardship. In today's world, where resource scarcity and environmental degradation are pressing concerns, transitioning towards a circular economy model is essential for minimising waste generation, conserving resources, and reducing the environmental footprint of our activities.

All our manufacturing facilities ensure compliance with applicable legal requirements as specified by the consents and authorisations. The waste is sorted by material type and shape and sold to recyclers for recycling or safe disposal. Hazardous wastes are sent to authorized recyclers or co-processors for material recovery or co-processing for energy recovery through waste-to-energy facilities.

In FY 2023-24, Dabur achieved a 12% reduction in waste intensity and a 7% reduction in absolute waste generation in operations in comparison to the previous year. Also, ~7,800 MT waste herbs were generated and reused in the boilers as green fuel and ~1,100 MT of miscellaneous packing wastes were reused.

Collecting and recycling post-consumer waste, along with ensuring greater awareness within communities and stakeholders regarding the negative impacts of pollution are key elements of our waste management strategy. Through effective waste sorting, collection, recycling and co-processing, we have managed to divert significant amounts of waste from reaching landfills and oceans.

Our immediate response was to create a nationwide model for Extended Producer Responsibility (EPR). Dabur's EPR journey started in 2016 by appointing a competent waste management company to conduct a waste management study across all Dabur units to help obtain authentic data about our EPR liability across all the packaging categories through qualitative and quantitative analysis.

In FY 2023-24, almost 73% of post-consumer plastic waste was recycled and the balance 27% was safely disposed of through waste to energy units, cement industries etc. Dabur continued to be a Plastic Waste Positive Enterprise in 2023-24, by processing 103% of the post-consumer plastic waste during the year. We have also been actively participating in events related to plastic neutrality, waste management and EPR changes by the Government of India, Pollution Control Board, FAME, CII, FICCI and others.

Educating and engaging stakeholders is also an essential part of driving the transition towards a circular economy. By raising awareness about the benefits of waste segregation at source, waste collection, management and recycling, promoting sustainable consumption patterns, and incentivising eco-friendly practices, we help our communities accelerate the transition towards a more sustainable and resilient future.

Working together with our society and members of the waste collector community, we are progressing towards a world where waste is minimised, resources are conserved, and economic prosperity is achieved in harmony with the planet's natural systems.

Some of the key initiatives undertaken during the year towards this end are:

My 10 Kg Plastic

What started as a household-level initiative aimed at creating awareness about waste segregation at source has today grown to become a community-level intervention that's bringing about social and behavioural change among citizens towards collection, segregation, storing and disposal of plastic waste. This intervention, which was initially operational in Delhi-NCR, was extended to Jammu in FY 2023-24.

This is a unique initiative as it does not impose any restrictions on participating residents and households. The only requirement is that residents deposit their household plastic waste with us and help ensure that it doesn't reach landfills and oceans.

As per the Central Pollution Control Board, the per capita plastic waste generation in India today stands at 10 kg, and through this program, we are urging citizens to collect 10 kg of waste and send it for recycling through our collection agents and become Plastic Waste Neutral Citizens.

Today, we are collecting segregated plastic waste from more than 300 societies and educational institutions across Delhi-NCR and Jammu under this initiative and reaching out to more than 2 lakh beneficiaries. In all, 79,375 kg (~79 MT) of segregated plastic waste was collected and channelized for recycling during 2023-24 through the My 10 Kg Plastic program. The year also saw us cross the milestone of collecting over 100,000 kg of plastic waste since the program's inception to end at 168,453.3 kg.

The citizens can give us a missed call on a dedicated number to schedule the waste pick-up. Our partner NGO Indian Pollution Control Association (IPCA) runs special vehicles that go to individual households and pick up the collected plastic waste. The amount of waste submitted by individual households is weighed and points equivalent to the weight are registered against each household. They are declared Plastic Waste Neutral Citizens when the total waste submitted by an individual reaches 10 kg. The Plastic Waste Neutral Citizens of India are also felicitated for their efforts. During the year, we donated garden benches made from recycled plastic waste to the housing societies that collected and submitted the largest quantity of waste during the year.The year also saw us conduct over 15 awareness workshops through our partner IPCA, targeting residents, students, housekeeping staff and maids.

Health & Well-Being of Waste Collectors & Their Families

Waste collectors are a key, yet much ignored, part of plastic waste management. At Dabur, we understand their importance in the value chain and have been reaching out to this community with special interventions planned at not only educating them about various types of waste but also addressing their health and safety concerns.

As part of this intervention, we donate gloves and masks to the waste collectors and create awareness about the importance of wearing protective gear to avoid facing health issues from exposure to waste. We also support their health and the education of their children.

Along with Bal Vikas Dhara in Delhi, we run an Ayurvedic OPD within the waste collector community, with an Ayurvedic doctor stationed there to diagnose and treat members of the community. In addition, we support the non-formal education centres which have been set up in their residential clusters to help their children enter the formal education system. A total of 582 waste collectors have benefited from the Arogya Health Centre.

We also worked with Sarthak Welfare Society to organize health camps, including special eye check-up camps, for waste collectors in Rewa, Madhya Pradesh. 'Nukkad Natak' (street play) was organized to create awareness among the farmers, children, and waste collectors about the ill effects of drugs and promote de-addiction. Special plantation drives were also organised with the community. The programs helped us reach over 5,000 individuals.

Along with the EcoEx Foundation, we organised a special waste segregation awareness session for 33 waste collectors in Gurugram, Haryana. The participants were educated on the sorting of waste, the segregation of plastic waste, and the importance of plastic categorisation, besides building awareness of the health and hygiene of waste workers & their families.

In Ahmedabad, Gujarat, Dabur works with the NEPRA Foundation to roll out a series of interventions on essential health and hygiene practices for waste collectors and their children. Together, we organised focused awareness sessions for women waste pickers to sensitize them about the right menstrual hygiene practices. Detailed discussions were held to educate them about menstrual cycles and the precautions they need to take during the menstruation period, including using a sanitary pad, regularly changing sanitary pads, safe disposal of dispose of the used pads, and ensuring sufficient rest and sleep, etc.

Awareness sessions were also organised to sensitise the children of waste pickers on cultivating healthy habits for a better life. The sessions also emphasised the importance of personal hygiene, including the importance of washing hands and dental care. Such interventions are aimed at empowering the community to take necessary precautions and make positive changes to improve their overall health and well-being.

Plastic Free Nainital

EcoEx Foundation, along with Go Clean Go Green Foundation and Dabur, organised a cleanliness drive, 'Plastic Free Nainital' in the north Indian hill station. As part of the drive, shopkeepers and residents were engaged in a plastic waste plogging exercise. They were encouraged to use cotton carry bags instead of plastic bags.

Beach Cleanup

Dabur employees participated in a beach clean-up drive at Juhu Beach, Mumbai, with our waste management partner ReCircle. This was part of a mega nationwide Beach Cleaning event organized to promote 'Jan Bhagidari' and public awareness regarding the prevention of marine pollution and the adoption of a sustainable lifestyle for healthy oceans.

We removed trash and debris from the shoreline to improve the aesthetics and protect marine life. Programs were also organised to raise awareness about the harmful effects of pollution on our beaches and oceans and to promote a sense of community responsibility.

We believe that this beach clean-up drive will not only make a positive impact on our environment but also foster a sense of unity among community members.

Safai Sathi

Dabur and ReCircle organised a series of social inclusion and awareness programs across various cities, reaching out to Safai Sathis and training them on safe, sustainable management of plastic waste. In addition to organising awareness programs, personal protective equipment and gear were distributed among waste pickers.

Special training programs were also organised to help build awareness about various types of plastic material, besides providing information about the economic benefits the community can gain through them. Special stress was laid on the use of Personal Protective Equipment for safe Handling of plastic waste, particularly during collection and segregation. They were also trained in the safe and correct operation of fire extinguishers. These programs have helped bring about a transformative social impact within our communities.

| Number of Safai Sathis Reached/Trained | ||

|---|---|---|

| City | Male | Female |

| Varanasi (Uttar Pradesh) | 38 | 12 |

| Bhadohi (Uttar Pradesh) | 54 | 6 |

| Gaya (Bihar) | 56 | 6 |

| Dahisar (Maharashtra) | 33 | 57 |

| Vellore (Tamil Nadu) | 15 | 63 |

| Ariyalur (Tamil Nadu) | 10 | 15 |

| Tumkur (Karnataka) | 15 | - |

| Bhilwara (Rajasthan) | 36 | 9 |

| Guwahati (Assam) | 45 | - |

| Silchar (Assam) | 19 | 1 |

| Uttarpara (West Bengal) | 12 | 48 |

| Rourkela (Odisha) | 6 | 24 |

| Sundargarh (Odisha) | 2 | 28 |

| Total | 341 | 269 |

Plastic Lao, Thaila Pao Campaign

Responding to a request from the Jammu & Kashmir administration, Dabur India Limited and the Indian Pollution Control Association (IPCA) launched a joint initiative during the Shri Amarnath Yatra 2023 to spread awareness about plastic waste management. Under this initiative, christened 'Plastic Lao, Thaila Pao', we promoted the usage of cloth/jute bags and discouraged single-use plastic carry bags. A special kiosk was set up at the Amarnath Yatra Base Camp at Bhagwati Nagar, Jammu, to help pilgrims and individuals submit their plastic carry bags and get cotton bags in return. This initiative was supported by the Jammu Municipal Corporation. Around 2,500 people participated in this initiative, which helped us collect 750 kg of plastic bags.

Festival Waste Collection & Awareness Drive

Dabur joined hands with ReCircle to organize a special Dry Waste Collection Drive in Mumbai during Diwali. In FY 2023-23, we had set for ourselves an ambitious target of collecting 20,000 kgs of waste from the community and ended the drive by collecting 20,369 kgs. Organised with the tagline "Light Up Lives, Not Landfills!", the drive was aimed at collecting and reusing old dry waste materials. This initiative saw significant support from residential communities, individuals, educational institutions, and corporations.

The materials collected during this drive included mixed plastic (Hard), mixed flexible plastic, paper, metal, glass, e-waste, utensils, clothes, etc.

Together with ReCircle, we also participated in a Christmas Carnival in Mumbai to raise awareness about waste segregation at the source and preventing them from reaching from landfills and oceans. We also built awareness on recycling waste and old clothes instead of discarding them in landfills.

Special engagement programs were also crafted for kids with activities featuring creative imagery of underwater animals, highlighting the repercussions of waste accumulation in oceans. The children actively participated in vibrant conversations and the waste-to-art activity, adding an exciting dimension to the entire engagement. planet and our stakeholders and strive to not only make our manufacturing process lean and green, but also our products.

Moving forward in this direction, we conducted a comprehensive Life Cycle Assessment (LCA) in FY 2023-24 for four of our Power Brands - Dabur Chyawanprash, Dabur Honey, Dabur Red Toothpaste and Dabur juices - that account for ~50% of our consolidated revenue and 58% of total production. The LCA, conducted in accordance with ISO 14040/44 standards by an accredited external partner, serves as a pivotal tool in identifying opportunities to minimise the environmental footprint of our products across their entire life cycle. From procurement of raw materials to manufacturing, distribution, consumer use, and safe disposal, we are committed to ensuring sustainability at every stage of our products' journey, in terms of resource and energy consumption, waste generation, and other factors. Several actions across the value chain are planned based on the LCA observations.

This initiative aligns with our commitment to the Science Based Targets initiative (SBTi) to achieve Net Zero Emissions. By conducting LCAs, we take proactive steps towards meeting our Net Zero Emissions targets, allowing us to analyse and address the key challenges involved in reducing emissions associated with our power brands, from sourcing to point of sale.

The appraisal results uncovered no huge negative natural or social effect or chance emerging from the items evaluated. We have utilized the existence cycle appraisal results to distinguish activities to lessen product carbon footprint.

As an organization with a portfolio of products based on Nature and natural ingredients, Dabur is committed to creating a greener future for our planet. We will achieve this by a multi-pronged approach encompassing all legs of the value chain -- from Source to Make.

Dabur strives to preserve biodiversity through a variety of initiatives. As the world's largest Ayurvedic product manufacturer, we believe in practicing responsible ecological management, including the sustainable cultivation of ayurvedic herbs. Dabur has committed to ensuring 100% afforestation equivalent to sourcing critically endangered herbs by FY 2025-26. As of FY 2023-24, we have achieved almost 78% afforestation. With two state-of-the-art nurseries in India and Nepal, in line with our plans to preserve ecosystems and support the conservation of rare and endangered herbs, we distributed 4.6 million saplings to local farmers for cultivation, in FY 2023-24. This not just protects the species, but also enhances the income of rural communities.

Our stated commitment to Water Positivity by 2030 remains steadfast through a combination of on-site conservation measures at our manufacturing locations and offsite community water conservation projects that benefit the villages around our operations at large. Against our commitment of 30% reduction in Water Intensity by FY 2025-26, we have already achieved 29% by the end of FY 2023-24.

Our relentless focus on moving to greener sources of energy is reflected in our public commitment to achieve over 60% Scope 1 and Scope 2 Energy from renewable and cleaner sources by FY 2025-26. We are well on our way to achieve this, crossing the threshold of 50% in FY 2023-24 itself.

These are a few glimpses of our multi-faceted result-oriented framework to Reduce, Reuse and Optimize natural resources in our sustainability journey.