Manufactured Capital

Dabur is today one of the most diverse players in the FMCG industry with a portfolio ranging from traditional Ayurvedic to core FMCG products like hair oils, toothpastes, shampoos, and beverages. This has resulted in a highly agile, flexible and future fit manufacturing network spanning 9 countries – India, UAE, Nepal, Bangladesh, Sri Lanka, South Africa, Nigeria, Egypt and Turkey. The geographical spread ensures that our products reach consumer households in 120+ countries across the globe.

During the year, the Board of Directors of Dabur India Limited approved an investment of 135 Crore for setting up a new multi-category manufacturing facility in South India, which will be our first site in that part of India.

All the manufacturing sites thrive on the “Kaizen” mindset, with the employees themselves contributing to over 2,600 Kaizens in FY 2023-24, spanning all areas from Safety, Productivity, Quality, Morale, etc, delivering cost savings more than 4 Crore.

This mindset, coupled with our investment in state-of-the-art manufacturing capabilities, gives us a big competitive advantage, while making more agile, flexible and creating factories of the future.

Key Highlights of FY 2023-24

- Supply Chain Management

- Technology, Product, and Process Innovation

- Research and Development

- Product Quality & Safety

- Circular Economy/Recycling of Product Packaging

- Occupational Health and Safety

Our 13 domestic manufacturing plants together produced approximately 4.74 Crore cases of a variety of consumer products to suit every need of our consumers. In addition, we worked with over 77 2P/3P contract manufacturers during the year to produce an additional 0.94 Crore cases.

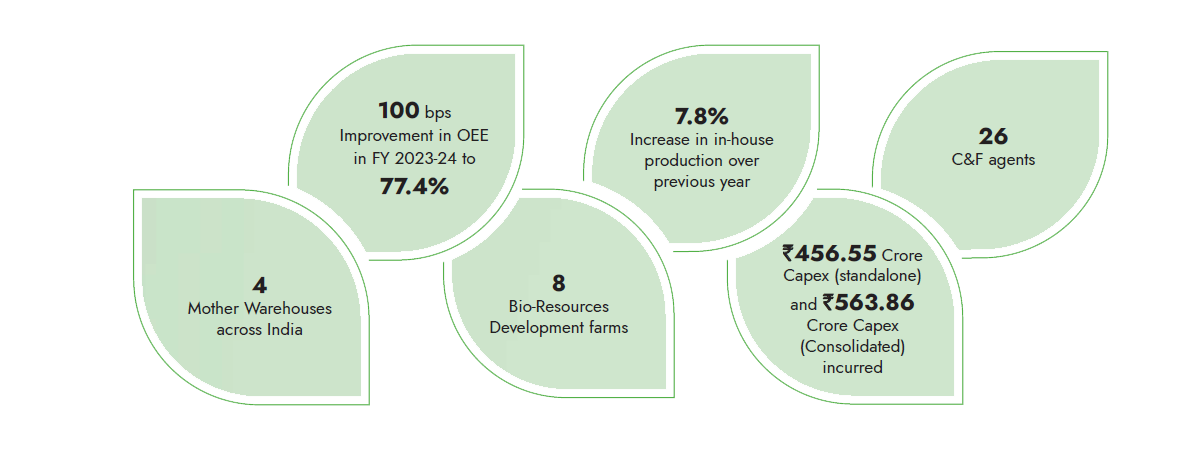

We have been investing in constantly upgrading our manufacturing capability and introducing automation in our units to streamline our operations. In FY 2023-24, Dabur invested 456.55 Crore towards Capex for upgrading its manufacturing capability and setting up new production lines in Indore, Tezpur, Jammu and Pithampur, besides integration of the latest state-of-the-art technology.

The journey on the path to creating a better future and leaving a greener planet for our future generations starts with improving our practices, processes and culture. Our science-based approach to NET ZERO EMISSIONS is designed to mitigate emissions across our value chain, and we are progressing smoothly on our mission to become a NET ZERO EMISSIONS Enterprise by 2045. It is a matter of great pride that Dabur India Limited achieved its ambition of Coal-free operations in FY 2023-24 itself, a whopping 12 months before its declared commitment.

Dabur is relentlessly focusing on ensuring the use of green energy within its operations to limit the environmental impact of its scope 1 (i.e. emission from sources owned or controlled directly by the Company) and scope 2 (i.e. emission caused indirectly by the Company upon use of energy purchased and used) emissions. In FY 2023-24, 51% of Dabur’s total energy consumption (scope 1 & 2) came from renewable sources. With the initiatives which we have executed in FY 23-24, usage of renewable energy is expected to increase to 55% by 2024-25. In FY 2023-24, 14% of our total energy in manufacturing units was generated from our own operations’ herbal waste.

The year saw Dabur sign an Open Access Solar PPA with Sunsure Energy, one of India's leading renewable energy producers. Under this PPA, Dabur will be able to offset a significant part of the total power needs of its Ghaziabad (Uttar Pradesh) factory. This is one of the many steps Dabur is taking towards decarbonisation of its operations. Through the PPA, Sunsure Energy will supply over ~1.7 Million units of green power to Dabur’s Ghaziabad factory. This will enable us to offset over ~0.8 million kgs of CO2 annually for the next 15 years.

We have also been investing in renewable energy projects within our facilities to replace fossil fuel with alternate clean fuels such as bio-briquettes and Piped Natural Gas (instead of furnace oil) as part of our efforts to proactively reduce our overall emissions footprint across operations. Efforts are also underway to optimise business-related travel and logistics.

Some of the key initiatives undertaken this year are:

| S.no. | Steps Taken on Energy Sustainability | Capital Investment (in Lakhs) |

| 1. | New Captive Roof Top Solar Power plant:

|

Opex Model |

| 2. | Bio-Briquette Boilers:

|

500 |

| 3. | Open Access Solar Investment for Sahibabad Factory (1.5 MW DC)

|

54 |

Including the above-mentioned initiative, we have incurred a total capital investment of 15.4 crores towards energy efficiency and sustainability measures during the year.

In a move that is a testament to gender parity across workplaces, Dabur India Limited has set up an all-women production line with 100% women employees at its largest-ever greenfield plant near Indore. In this first-of-its-kind development, a crew of 20 women are engaged in the production of Dabur's range of Vatika and Amla Hair Oils – a range of products.

'Made For Women, By Women'.

The move is part of our efforts to build a more diverse workforce and promote women's empowerment in the manufacturing industry. We will be further expanding this initiative with the inclusion of 30 more women in its factory workforce, going forward.

Dabur has always been committed to the principle of equal opportunity in employment. We continue to make progress on our commitments as we enhance representation and inclusion across our organization. Setting up an all-women production line is one step forward in this direction and seeks to not only transform a traditionally male-dominated manufacturing sector but enhance the lives of local women and the community in the process.

This all-women production line has the capacity to produce over 2.5 Million packs per annum and will be operating in 3 shifts. The groundbreaking move is not just a powerful statement for gender equality and women's empowerment in the workplace, but also serves as a shining example of breaking stereotypes and providing equal opportunities. The introduction of an all-women workforce has proven to be a catalyst for higher safety, productivity, enhanced team cohesion, exceptional efficiency, attention to detail, and commitment to quality, translating into a 10% increase in the factory's overall productivity.

A special video honouring these 'Vatika Women of Substance' was launched on the occasion of International Women's Day.

Our supply chain management is responsible for planning, sourcing, and timely delivery of more than 3.30 lakh tonnes of raw and packing material and more than 67 million cases for finished goods across the country. Our ability to delight customers rests on a strong network of 4 Mother Warehouses and 26 C&FAs that together help ensure that our products travel to around 7,400 towns and 606 districts across the country.

At Dabur, we believe that our suppliers, service providers, channel partners, dealers, distributors and vendors make significant contributions to our success and we treat them with respect. We are also focusing on building and strengthening this infrastructure to address the future needs of the organization. We work closely and cooperatively with our suppliers and customers to ensure quality standards are maintained across the Supply Chain.

We are continuously working to improve our systems and processes to deliver the right data at the right time to support Supply Chain Efficiency our growth agenda as our factories go about creating quality and highly efficacious products that Health & Personal Care needs of our consumers. We have identified digitisation of our supply chain as the core lever to transform our end-to-end supply chain planning capabilities, encompassing demand, supply, inventory, production, and materials planning. This enhancement will boost our agility and strengthen our supply chain resilience.

With consumption habits in rural India increasingly mimicking their urban counterparts, Dabur has been creating a portfolio of products, albeit at affordable price points, to cater to consumers in Tier 2, 3, and beyond. We are aware that the Tier 2 and Tier 3 towns will be significant growth contributors in the future. Our warehousing infrastructure is constantly evaluated, upgraded and even relocated in some cases to meet the future growth projections, particularly from these towns. We recently strengthened our infrastructure in the northeast, which was a more strategic location to serve demand faster as per the new demand patterns.

Technology has been the key lever to accelerate the performance of our supply chain and make it more agile, resilient, and efficient. Dabur has been among the first movers in the industry to adopt best-in-class technologies to transform its supply chain operation. We have already implemented an Integrated Business Planning solution and will be expanding the usage to the full portfolio to further improve our planning of demand, supply and distribution. Robotic Process Automation is also being increased in the areas of order processing for alternate channels to handle it more efficiently. This has helped minimise manual work and has reduced the order-to-billing time. To drive greater efficiency in Logistics and Distribution, truckload and route optimisation is being implemented along with GPS tracking for transport.

Multiple digitalization projects are part of the future roadmap for supply chain transformation. Dabur is making significant progress in this direction and our endeavour is to stay ahead in adopting technology to our advantage.

In line with our Net Zero Emission ambitions, we are in pursuit of transforming our supply chain by increasing the usage of Vehicles using alternate fuels in our transportation fleet in downstream operations to assist last-mile product distribution. We are among the first movers in the industry to conduct trials with vehicle manufacturers to pilot 7 MT electric vehicles that can serve the demand for longer routes.

Dabur is constantly looking for the latest and cutting-edge technologies to improve our performance and consumer experience. Technology adoption efforts have resulted in multi-pronged benefits such as product improvement, cost reduction, improved line efficiencies, and import substitution. We continue to engage with domain experts, device manufacturers, industrial institutions, digital experts and start-ups for ideation and adoption. We invested 66.8 crores on imported technologies during FY 2023-24.

Some of the technologies introduced in FY 2023-24 are:

Manufacturing Processing Systems – Dabur has commissioned for the first time, a new high-speed Carbonated Soft Drink manufacturing processing line in Jammu, which can process & pack 18,000 bottles per hour.

Primary Product Filling Systems – Ultra high-speed PET bottle filling line with German technology was installed at our Indore plant. This line can pack SKUs from 150 ml to 2 L packs at 36,000 bottles per hour, with end-to-end automation.

End of Packing Line Automation – We are using robotic pallet equipment to pack 4 SKUs simultaneously, which enables efficient management of multiple SKUs on different lines to improve manpower productivity. At our Indore unit, Dabur has started palletizing with box packers and fast juice filling lines.

Digital Technologies – As part of our Digital Transformation journey, Dabur has implemented best-in-class technology solutions centered on new-age technologies like Industrial IoT 4.0 for Improved Asset management, productivity monitoring, Freight Optimization solutions and Robotic Process Automation on certain aspects of customer service.

| S.no. | Technology | Year of Implementation | Key Benefits | Amount (in Lakh) |

| 1. | Ultra high-speed Automated PET bottle filling line with German technology which can pack SKUs from 150 ml to 2 L packs at 36,000 bottles per hour | FY 2023-24 | Automated line, Higher productivity, with various product flexibility, better customer service | 4,658 |

| 2. | Automatic batch manufacturing system(PLC based recipe consumptions) in RTP | FY 2023-24 | Product mix accuracy with optimized energy use, reduced wastage and better operational cost | 630 |

| 3. | High-speed Oil filling lines for Anmol coconut oil | FY 2023-24 | Higher productivity, which lower manpower and lesser Utilities consumption | 600 |

| 4. | UHT with twin capability (used as sterilizer and UHT, based on product temp. requirements), eliminates the need for 2 separate systems. | FY 2023-24 | Flexibility in operations with assets & infra optimization | 590 |

| 5. | High recovery RO >90% (multistage, high-performance membranes), generating lesser rejects and lower raw water consumptions. | FY 2023-24 | Lower raw water consumptions, lower water wastages and better operational cost | 200 |

| Total | 6,678 |

The year 2023-24 saw Dabur successfully complete one of the largest and most complex cloud migrations in the Indian Consumer Goods industry, making us the first Indian FMCG Cloud-Only Enterprise. As a future-ready enterprise, Dabur’s adoption of a cloud-only approach will significantly improve business resilience and enhance control of the IT landscape, helping the company augment its services for retailers, partners, employees, and consumers. Dabur will benefit from the 360-degree visibility over all its operations while enjoying increased efficiency, transparency, and agility.

Agility and business innovation are crucial to address the changing market dynamics and consumer expectations. Leveraging the power of the cloud, artificial intelligence and its strong data foundation will transform Dabur into an Intelligent, Sustainable Enterprise, with the ability to innovate new products and services faster and provide superior customer experiences. The move is also in line with Dabur’s commitment to curb carbon emissions and achieve Net Zero Emissions by 2045.

The creation of a digital core will enable Dabur to access real-time data insights and, in turn, adapt to evolving customer and market demands with agility and speed. Dabur worked with SAP and Microsoft to deliver this transformation in just ten months with no disruption to business operations. Accenture was the implementation partner; Thoucentric, a Xoriant company, was the Program Management and Governance partner for this digital transformation exercise; and Azure was chosen as the primary cloud platform.

The program involves the complete migration of our applications from our On-Prem Data Center onto Microsoft Azure and SAP RISE. The complete set of Non-SAP applications is now hosted on Azure, whereas all SAP applications & modules have been hosted on RISE with SAP Cloud platform. With this move Dabur has become the foremost Indian FMCG enterprise to use emerging technologies such as Open AI for its digital transformation. RISE with SAP provides Dabur with a complete offering of ERP software, industry practices & outcome-driven services.

We are committed to operational excellence by investing in the right capabilities and capacities, while adopting best practices. At Dabur, we hold regular Kaizen melas across all our manufacturing units to increase employee engagement, to tap into the collective knowledge of our workforce, and develop problem-solving skills in our employees.

In the year 2023-24, our employees submitted a total of 2,650 Kaizen projects, of which 2,210 were implemented, which helped us achieve significant savings in manufacturing operations.

Brand Dabur evokes feelings of Trust in the minds of our consumers. Our brands symbolize Quality, Ethics, Integrity, and Perfection for our billions of consumers who we call the Dabur family. We are committed to delivering high-quality products rooted in nature and prepared from sustainably sourced natural ingredients. Drawing inspiration from ancient Ayurvedic wisdom, our products are designed to uphold our pledge to enhance the Health and Well-Being of every household.

We adhere to rigorous internal quality standards, diligent processes, and robust quality assurance practices. Our hygiene and quality standards meet both Dabur's stringent internal benchmarks and the requirements set by FSSAI.

All our products provide comprehensive quality and safety information, such as sourcing of raw materials, product contents, and safe usage instructions, prominently displayed on packaging materials.

Our unwavering commitment to compliance is reflected in our track record, with zero incidents of non-compliance related to regulations or voluntary codes pertaining to product information and labelling reported in FY 2023-24.

Way Forward

Dabur's manufacturing network aims to be a thought leader in the Sustainability space and contribute significantly to the organization’s Net Zero Emission ambition. With our relentless push to embrace sustainable power and fuels, all our own manufacturing sites will have over 60% of their energy contribution coming from renewable fuel sources by FY 2025-26. While energy and water intensity have reduced significantly from the base year, the focus will also be on reducing energy consumption and water abstraction through multiple initiatives.

Dabur also believes in a diverse manufacturing workforce. With its Hair Oils line in Indore – the first line in the Dabur network to be operated by women in all three shifts – standing as a beacon of excellence, this push will be scaled up, going forward.

By embracing IoT (Internet Of Things), latest trends in manufacturing and processing technology, investing in capability development in its workforce, Dabur’s manufacturing network continues to fulfil its role as the backbone of the organization while it goes about developing products to delight consumers.